Shurflo Liquid Pump Diagram – Installation Parts Supply

Faulty installation of liquid pumping devices can substantially lower their performance by up to 30%. It’s essential to grasp the operation of the Shurflo Pump schematic for maximum efficiency and robustness. Each part within the diagram serves an essential purpose in the operation of the Pump. We will explore the value of understanding these Shurflo fittings, utilizing the diagram to show their configuration and how they operate in unison.

Installation Components Supply is your primary source for every Shurflo Water Pump element needed for installation and upkeep. Gaining knowledge from the Shurflo Water Pump parts diagram enables users to expertly handle installation and maintenance. This knowledge assists in creating savvy decisions for the effective and safe operation of their water pumps.

Understanding Shurflo Pump Systems

Shurflo Pump systems are at the intersection of innovation and functionality, satisfying the needs of various uses. This portion seeks to provide an in-depth overview of Shurflo Pump models, their distinct functions, and the advantages of selecting these devices. They are celebrated for their technological sophistication and effectiveness.

Overview of Shurflo Pump Types

Shurflo’s line-up comprises pumps like the diaphragm and farm series, designed for multiple needs. The membrane models are celebrated for their sturdy design and efficiency in moving liquids. Notable examples include the 2088-343-135 and 2088-343-500 provide strong performance with remarkable flow and pressure specifications.

The agricultural series, alternatively, is engineered for effective fluid transport in greenhouse applications.

Implementations of Shurflo Pump Systems

The adaptability of Shurflo Pumps allows their use in a diversity of environments. They are commonly used for:

- Agriculture: Provides solutions for crop irrigation and fertilization.

- RVs: Ensures a consistent water supply with safe pressure levels.

- Domestic: Perfect for yard upkeep and home Water Pump installations.

This adaptability permits these Pump systems to blend seamlessly with various setups, demonstrating their multifunctionality.

Advantages of Using Shurflo Pumps

Opting for Shurflo Pumps brings several advantages. Their ability to self-prime eliminates the need of manual priming. They also possess chemical resistance, ensuring longevity in harsh environments. Readily available Shurflo membrane Water Pump parts streamlines servicing, boosting service life while minimizing downtime. Other advantages of Shurflo Pumps include:

- Steady output adjustable to various pressures.

- Easy installation supported by the Shurflo pumps parts catalog.

- Diverse pump fittings for seamless integration with existing setups.

With these features, Shurflo Pump systems deliver efficiency and reliability. They ensure operation continuity, assuring users of reliable operation.

Shurflo Water Pump Diagram and Its Importance

The Shurflo Water Pump schematic is critical for understanding its components and functions. By studying the Shurflo Pump schematic, users can construct, troubleshoot, and preserve optimal performance. This schematic is crucial for determining the needed Shurflo Water Pump parts. Accurate assembly guided by the schematic guarantees peak performance.

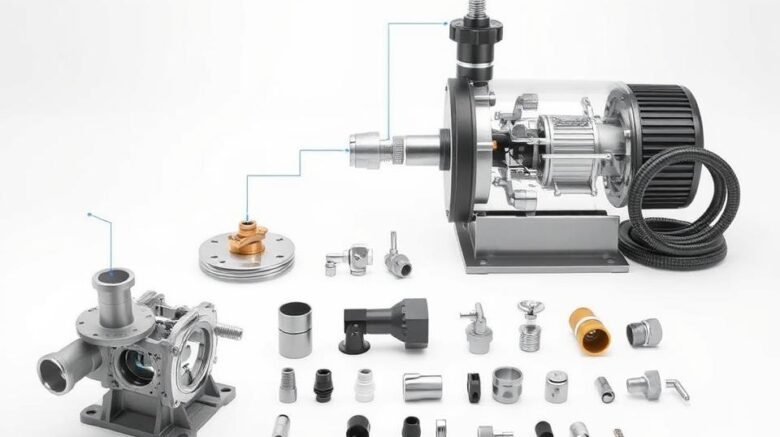

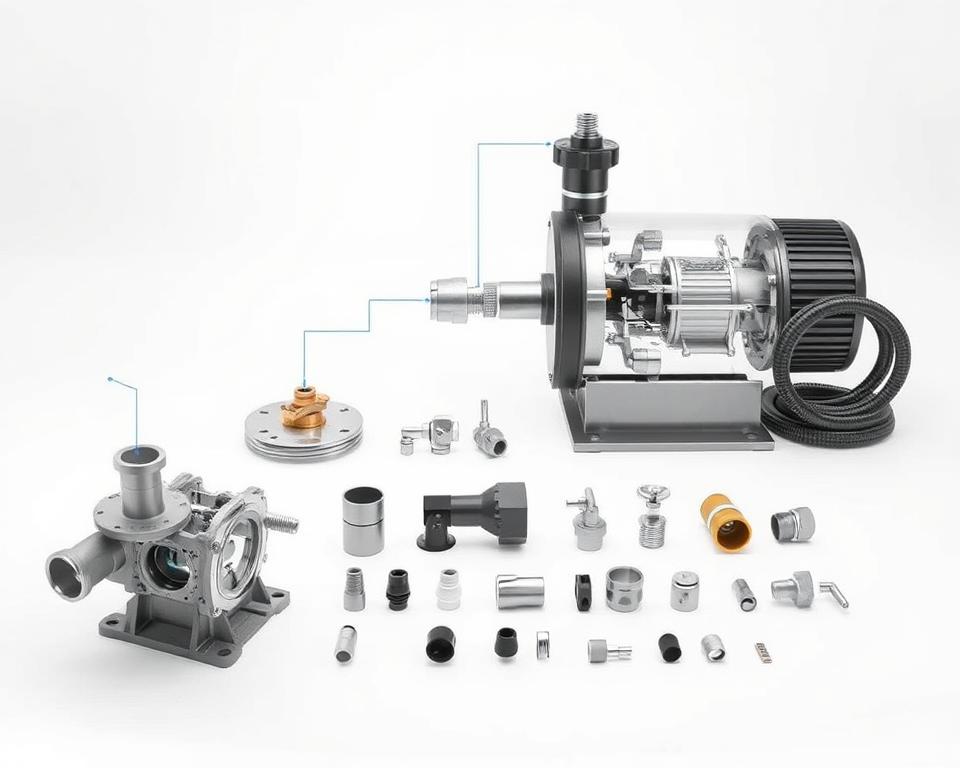

Key Components in the Diagram

The Shurflo Water Pump assembly diagram illustrates critical elements required for effective function:

- Engine: The engine, the central unit of the Pump, powers the rotor, enabling flows from 41 to 168 GPM.

- Diaphragm: Assists in maintaining steady output and pressure.

- One-Way Valves: Essential for blocking reverse flow, these valves guarantee that fluid flows in the right direction.

- Casing: With a max pressure of 200 PSI, the casing secures longevity.

Understanding the Shurflo Water Pump Diagram

To analyze the Shurflo Water Pump diagram, one must note specific symbols and notations:

- Understand the configuration of elements illustrated.

- Identify the flow direction as shown by arrows among parts.

- Examine the remarks for information on wiring dimensions and mounting configurations.

Mastering this diagram is crucial for proper assembly, maintenance, and identifying key components.

Fitting Shurflo Water Pumps

Fitting a Shurflo Water Pump can improve the operation of any water setup. Understanding the required procedures and parts is crucial for a proper assembly. This tutorial outlines essential procedures and necessary equipment for a triumphant installation.

Step-by-Step Guide to Installing a Shurflo Pump

- First, assemble all equipment for shurflo pump installation. Verify that you have a suitable screwdriver, wrench, and 50-mesh strainer.

- Install the 50-mesh strainer at the Pump’s intake. It is advisable to employ a flexible hose for inlet connections to reduce fitting stress.

- Utilize a 1/2” to 3/8” barb splicer to fasten tubing attachments. To avoid leaks, opt for durable tubing equipped with Oetiker clamps.

- Ensure the Pump is linked to a correctly grounded outlet. A professional electrician should handle this to meet regional standards.

- Inflate the accumulator tank to 50 PSI using clean air or nitrogen. This is vital for achieving ideal pressure levels.

- Mount a SHURflo 65 psi pressure reducer at the Pump’s inlet to maintain appropriate pressure conditions.

- Finalize the configuration by joining every element. Avoid overloading the motor’s amperage; incorporate thermal breakers for additional safety.

- Test the system and check the pressure switch’s functionality.

Tools and Parts Required for Installation

| Item | Information |

|---|---|

| 50-mesh filter | Strains particles at the Pump’s intake for maximum efficiency. |

| Bendable hose | Ideal for connecting the inlet, lessening stress on attachments. |

| Barb splicer | 1/2” to 3/8” connection for secure tubing attachment. |

| Storage tank | Charged to 50 PSI to ensure stable operation. |

| Switch | Regulates operation by monitoring pressure conditions. |

| Electrical supplies | Essential for proper electrical hookup, following local codes. |

| SHURflo 65 psi pressure reducer valve | Reduces water pressure entering the pump for consistent operation. |

Diagnosing Frequent Problems in Shurflo Pumps

Understanding how to remedy frequent problems in Shurflo Pump systems enhances performance. This section provides a problem-solving manual. It helps users diagnose and resolve frequent problems to ensure smooth operation of the pumps. Troubles such as non-operation, poor flow, and excess noise are resolved using practical methods.

Frequent Faults and Corrections

Various conditions may result in malfunctions with Shurflo Pumps. Below are key problems and their solutions:

- Pump runs but no water flow: Assess the water supply level, inspect piping for clogs or impairments, ensure adequate priming, and test Pump performance.

- Pump fails to start post-winterization: Revisit correct winterizing steps, check that valves remain open, confirm wiring integrity, and look for any component damage.

- Pump cycling on and off: Inspect for leaks, check for air in the system, ensure appropriate pressure settings, and verify the functionality of the pump and pressure switch.

- Noisy pump: Inspect for loose connections, add padding under the pump, insulate water pipes, and ensure proper installation of the unit.

Troubleshooting Manual for Shurflo Pumps

A comprehensive Shurflo Water Pump troubleshooting guide assists users in quickly identifying issues. Below is a summary table of common problems with solutions:

| Frequent Problem | Possible Reasons | Remedies |

|---|---|---|

| Operation without liquid movement | Deficient water supply, clogs, incorrect priming | Check tank level, inspect water line, verify pump function |

| Failure to start | Improper winterization, closed valves, electrical issues | Reexamine procedures, unlock valves, inspect electrical links |

| Pump cycles on and off | System leakages, trapped air, incorrect pressure settings | Examine for leakages, eliminate air, modify pressure controls |

| Excessively loud operation | Unsecured fittings, poor mounting | Fasten components, apply padding, insulate connections |

Comprehending the shurflo pump exploded view aids in identifying the parts causing problems is key to proper troubleshooting. Following these recommendations secures consistent performance and upkeep.

Bringing It All Together

Comprehending the Shurflo Water Pump diagram is key for optimal Pump operation.

Employed across sectors such as RVs and agricultural applications, proper installation is fundamental for reliable results.

Knowledge of the schematic’s components enables proficient assembly and upkeep of systems.

For acquiring every necessary Shurflo Pump part and service, Installation Parts Supply is unrivaled, delivering extensive service along with vital instruments and elements. Such support guarantees proper assembly. By adhering to proper plumbing, wiring, and upkeep of parts like the strainer, the operational life and efficiency of the Pumps are boosted.

This write-up provides the insights needed to enhance overall Shurflo system operation. Employing Shurflo Pump technology alongside these installation recommendations readies users to overcome any obstacles confidently.